Home › Forums › Technical Information › Tale of Grumman Camera Ports

Tagged: 337, camera ports, field approval

- This topic has 0 replies, 1 voice, and was last updated 7 years, 10 months ago by

Roscoe Rosché.

Roscoe Rosché.

-

AuthorPosts

-

-

June 23, 2016 at 15:53 #5695

Roscoe RoschéKeymaster

Roscoe RoschéKeymasterAs Ken would start out, “In a galaxy far, far away,……”

So the year is 1992, and we are having typical November weather at the Stennis Space Center located in Bay St. Louis, Mississippi, meaning if we could we would be wearing shorts and tee shirts. The rain that had been coming down steady all day was not letting up, so we decide to take our lives in our hands and dine in the base cafeteria.

Not all that busy, we had choice of seating and choose a table for 6 for the three of us. Two of us were recent pilots (last 2 years) and the third was interesting in taking lessons and wanted to see what we could give in the way of information and help. About 10 minutes into the lunch we were approached by one of NASA’s engineers who asked if he could sit in on the pilot talk. This engineer was Chuck Thurman.

Chuck was the engineer responsible for NASA’s Learjet (23) which was used for thermal image capture from the air using a nitrogen cooled infrared Inframetrics camera. As Chuck explained, the Lear could not operate due to safety below 10,000 feet in case they ingested a bird at low altitude, and they also could not fly slower than 170 knots. This would make getting the data for Huffman Prairie (the location of the original and second hangar that the Wright Brothers build on what is now Wright-Patterson AFB just east of Dayton, Ohio) difficult and of low quality. What was needed was something that could fly under 100 mph and fly at 500, 1000, 2000, 3000 feet in passes at 12 different times of the day. The Cessna they had investigated was too thermally polluted by the exhaust stream from the engine for the belly camera port to get good data. Hot gas at 2 feet from the camera masked the minute details of the ground 1000 feet away.

Further explanation revealed that NASA predicted that the ideal shape of the fuselage to help prevent this thermally pollution of the bell was a boxy shaped plane like an experimental (remember this is 1992) which they could not use, had to be a production certified plane. So I told Chuck about the shape and construction of the Grumman. I had remembered that Jim Bede had explained that the box shape of the fuselage helped break the propeller swirling air from making it around the fuselage like in Cessnas and Pipers with rounded bellies.

Lunch was long over when we got up to go back top work, but we were going to try the Grumman for some thermal testing that weekend at the local airport to the base.

That weekend we verified what Jim Bede had told us, the exhaust plume goes almost straight back from the pipe causing some thermal pollution only near the right side of the fuselage after about 60 mph. We had the Inframetrics bolted to the main right landing gear facing down with the cables taped to the fuselage. This proved that the Grumman would work if they could find one with a camera port.

So it is late 1992, I have had my license for 16 months, I have 1000 hours in my logbook (784 the first year!) and my career as a government employee is coming to a close. I was a contractor since September when my time expired, but they hired me back for transition. So here was my dilemma, find a non-government job, or put camera ports in my Grumman and start my own flying business. Thus, SurveyAir was born.

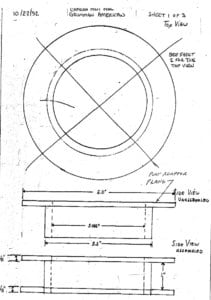

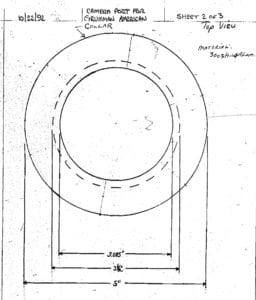

Started off with calling the Baton Rouge FSDO office and asked about the process of putting camera ports in a plane that had no STC or field approval of accomplished work. Keith (FSDO guy) asked me why I wanted to put holes in a perfectly good airplane. I knew right then this was going no where. So I called Don Lockhart, that’s right, Mr. Carp himself. As soon as I told Don my tale of woe from the Baton Rouge FSDO, we said only this, “Draw up what you want and where you want it, and send it to me.”. Which I did that night and mailed him the drawings. Don was an A&P with contacts at Louisville’s (named after King Louis of France” FSDO. Three days later he called to say the drawing were approved, have two camera ports made according to the drawings, and then come to Louisville for install.

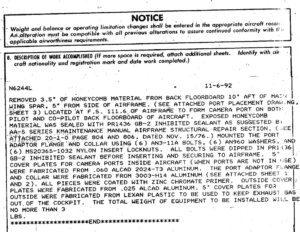

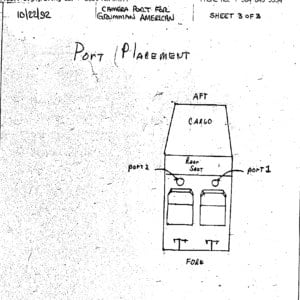

And that is what I did. Two aluminum camera ports with plexiglass covers, 2 covers of 1/8 inch alum for inside when not in use (so you did not step into the 3.5 inch hole in the back where the passengers place their feet.) and 0.032 alum covers for travel on the outside. These went with the LOU in December to be installed.

The first on installed was the right one (which would be the visual side). You have to take a big breath to drill a big hole in the floor of your plane but it can be done. We bonded in the camera port and then let it cure overnight. The next day the FAA inspector came to the hangar to see the install and asked about a g-test on the port. Well the port weight 1.0 pounds so I stood on it to prove that a sustained load of 180 g’s would not harm the plane or that it would come out. Since each camera head only weighted 5 pounds (huge by today’s standards) we had tested a larger load than 20 g’s and not an instantaneous load either.

Thinking we were in the clear he then asked how we planned on conducting a smoke test to make sure exhaust gas would not come into the cabin when camera where installed with no covers. Don asked me if I had any cigars with me and I did. So Don proposed that he fly my Traveler, the FAA guy sits in the co-pilot seat, I sit in the back and after reaching our cruise altitude, I take the covers off and see where the smoke goes.

It is a rare treat to be able to sit in the back of your own plane and smoke a cigar. Oh the smoke, it went right out the bottom of the plane. Success!

So with my newly signed off Field Approval and 337 we put the other port in and I departed for home, New Orleans.

Here are two YouTube videos showing thermal and visual data captured in route and at Wright Patterson’s Huffman Prairie.

Visual Video Here:

Infared Video Here:

Here are the Sheets from the 337 if you are interested.

Cheers

Roscoe

Yankee-Aviation.com

513-519-7008

-

-

AuthorPosts

- You must be logged in to reply to this topic.