Home › Forums › Operation of Our Aircraft › Engine Management › Engine Data Management

Tagged: % of Power, avionics, carb temp, engine, JPI, MAP, MAP Install, Monitoring

- This topic has 24 replies, 14 voices, and was last updated 3 years, 5 months ago by

Richard Harrison.

Richard Harrison.

-

AuthorPosts

-

-

March 21, 2015 at 08:53 #1396

Jim FreemanParticipant

Jim FreemanParticipantDoes anyone on the forum have an engine monitoring instrument in their aircraft? I’ve been looking at JPI’s EDM 700 lately, and just wondering if anyone had any insights. Thanks!

-

March 23, 2015 at 20:28 #1399

Matt WingParticipant

Matt WingParticipantI have a JPI 730 installed and after flying with it for over 2 years now, I can’t imagine flying without it for any length of time.

If you’d like to discuss call me on my cel phone 937.604.3397

Thanks

Matt

-

April 15, 2015 at 16:23 #1557

Chris Hodgson

ParticipantI just installed a JPI 830 on my Tiger and with a total of 2.6hrs. I can tell you they are worth the money, it is like having a someone else there with you pointing out what you are doing wrong (or right)

Chris

-

September 20, 2015 at 22:15 #2048

Roscoe RoschéKeymaster

Roscoe RoschéKeymasterJim,

You can give me a call about the various models. Matt has a 730 in his Cheetah (with many extra sensors), I have a basic in my Tiger, we just installed an 830 into the 6-cyl Tiger (oh joy!), and have a 830 going in next week in a cheetah with Tiger motor.

Happy to advise,

Roscoe

JPI Dealer

Yankee-Aviaiton -

October 18, 2015 at 15:53 #2824

Jim FreemanParticipant

Jim FreemanParticipantThanks everyone! Finally got it put in… installed the JPI 700 into the Tiger, and included RPM and fuel flow to help monitor trends. (We also already had the Fuel Flow transducer installed for an FS450.)

Put a dozen hours on it so far and love it! LOTS more information at my fingertips than with the old imprecise EGT gauge we had.

Anyway, just thought I’d give an update. Happy flying!

Jim

-

November 8, 2015 at 19:52 #3026

NathanParticipant

NathanParticipantFlown another dozen hours in the Tiger and have to agree it is a fantastic tool. Took some time to get the hang of using the LeanFind feature and how the information was presented, but it beats the heck out of the old EGT.

Just downloaded all the stored data from the JPI the other day and it is amazing the sorts of things you can pick out. Definitely a worthwhile install! -

March 8, 2016 at 17:14 #3943

Mike BrownParticipant

Mike BrownParticipantI just purchased a EDM-830 for my O-320 Cheetah. I’d like it to do everything it is capable of. It came with a MAP sensor. Where and how is the best way to install the sensor?

Carb Temp is an option. Can that simply be installed in the air intake near the carb?

-

March 8, 2016 at 20:20 #3944

Roscoe RoschéKeymaster

Roscoe RoschéKeymasterMike,

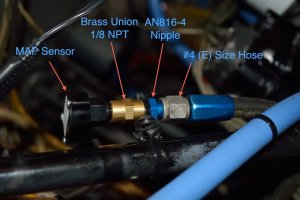

The easiest way is tap into the #4 cylinder upper primer port (remove the plug), then thread in the 1/8 NPT to AN nipple. Then cut a 1 inch hole in the rear baffle, run a #4 size hose through the hole now with grommet installed, then into whatever fitting you need to thread into the map sensor. Anchor as needed with Adel clamps. Keep the map sensor out from the cylinder area (for heat).

I do this in Ohio since we tend to need a 4 primers to start in winter, but based on your clime, you might plug into the lower #3 primer port and seal off the primer line to that cylinder. Like the other option, 1/8 NPT to AN nipple, hose, fitting and sensor.

I can take a picture tomorrow at the airport.

As you can see above, the MAP sensor is on the left (black) then into a brass union (1/8 NPT) and then an AN816-4 for the hose connection.

For the cylinder use an AN816 – 4 nipple for the hose, just like above.

For the cylinder use an AN816 – 4 nipple for the hose, just like above.Roscoe

Yankee-Aviation.com

513-519-7008 -

March 8, 2016 at 20:57 #3945

Roscoe RoschéKeymaster

Roscoe RoschéKeymasterCarb Temp is not to show incoming air, there is a port on the carb (plug in it now) that can be removed so the probe shows venturi temp which is what you want to check for carb icing. OAT you already have.

Roscoe

Yankee-Aviation.com

513-519-7008 -

March 10, 2016 at 14:12 #3954

Mike BrownParticipant

Mike BrownParticipantI have looked over the Carburetor and don’t see any place to install a probe, or at least a threaded plug. There are two areas on the front, one high on the float bowl and one just below the throttle plate that have swedged lead plugs. Is this the port you are referring to? If so, will this need to be drilled out and tapped for the probe?

-

March 10, 2016 at 19:21 #3964

Roscoe RoschéKeymaster

Roscoe RoschéKeymaster -

March 11, 2016 at 11:14 #3966

Mike BrownParticipant

Mike BrownParticipantI found a PDF with some detailed information on drilling the carb and installing a probe. I feel much more informed now.

Mike

Attachments:

You must be logged in to view attached files.-

March 14, 2016 at 11:38 #4011

Mike BrownParticipant

Mike BrownParticipantI just want to note that this PDF covers the process of drilling and tapping the Marvel carburetor. It refers to threading the hole with a 1/4-28 UNF tap. The JPI Carburetor Probe is a 1/4-24 UNS(Unified Special Thread – 60-degree flank angle) thread. Use the appropriate tap.

-

-

March 25, 2016 at 22:35 #4078

Mike BrownParticipant

Mike BrownParticipantUPDATE: Although the JPI website FAQs states the thread is a 1/4-24, it is not. I received my probe today and it is a common 1/4-28. It pays to have all the parts in hand before you start modifying.

-

May 6, 2016 at 18:41 #4884

Tracy NorrisParticipant

Tracy NorrisParticipantMike,

Interesting! I installed the JPI-optional EDM-830 Carb Temp probe on my O-320-E2G with Zero Modifications. There is a hole with a plug located forward-center and high on the carburetor. I removed the plug and installed the probe – took about 5 minutes. Mine is in the same location as the location Roscoe provided but was tapped with the correct thread, etc.

If anyone is interested in what a carb temp plot looks like, click the following link and select “CARB TEMP” from the pull down menu on the right:

N9683U Flight Record -

July 13, 2016 at 02:33 #5782

David

ParticipantI noticed everyone posting has installed JPI analyzers. I am considering the Electronics international CGR-30P as this would be a replacement of the stock tachometer, leaving more real estate on the panel. Anyone have experience with this instrument? Pros/cons vs. the JPI 830? Also, if I eventually get the powerflow, would it better to just have the engine analyzer installed after the powerflow STC to prevent re-configuring the probes/wires, or does it not matter?

Thanks,

David-

July 5, 2017 at 14:44 #7349

CurtParticipant

CurtParticipant+1 on your request, David! I really like the Electronics International CGR-30P design – and right now there is a $700 rebate! I was a bit confused though because on Aircraft Spruce’s website, it has the CGR-30P STC and Approved Model List – and Grummans are NOT on the list. Does that mean I can’t install it? New Tiger owner here….

-

-

July 12, 2017 at 21:55 #7374

Bob Dutton

ParticipantCurt,

You can install the EI CGR 30P in your Tiger. Mine was installed in my 91 AG5B in March of this year, and so far I really like it. It has replaced all of my primary engine instruments and I like having MP and RPM displayed at the same time along with cylinder and EGT temps. AA5’s are listed under True Flight Holdings, LLC which holds the rights to most Grumman, American General and other versions of the AA5’s.

As far as I know, JPI’s systems (730’s or 830’s) cannot replace the primary engine instruments at this time. I believe the JPI 900 (930?) is certified but it’s way expensive. But be aware, the battle between JPI and EI fans is intense and no matter which system you choose, someone some where is sure to tell you that you made a bad choice.

-

July 14, 2017 at 07:06 #7388

CurtParticipant

CurtParticipantThat’s great news, and thanks for the information, Bob. Glad you enjoy you CGR30P – and I’ve ordered the instrument and had it shipped to my mechanic at FletchAir. I’ve got a rebuilt engine coming into my Tiger so I want to keep a close eye on those temperatures! I called EI to get some more information on the engine analyzer and I was very impressed by the customer service. Really looking forward to having it!

Thanks again for the info! -

June 6, 2019 at 23:16 #12518

PatParticipant

PatParticipantGreetings,

At annual this year we installed a JPI EDM 730. On the first flight in 68 degrees, fuel flow 12.2 gph, 85kts, we had cylinders indicating well over 400 on climb out, settling down in the 380s in cruise. EGTs were in the 1360 range with the highest EGT being a cylinder other than the one with the hottest CHT. We are very confused now. Newly overhauled 0-320 180 hours ago from Penn Yan, high compression cylinders, new baffling. We’re going to test the probes, download the data and talk to JPI. Any other ideas?

Pat Hendren/Jenny Shu

-

July 18, 2020 at 05:08 #14397

gFlyer

ParticipantHi,

Planning my installation of a JPI EDM 830. Does anyone know if I can use the existing oil pressure sensor parallel wired with the EDM 830?

-

July 18, 2020 at 09:11 #14400

Roscoe RoschéKeymaster

Roscoe RoschéKeymasterThe JPI unit comes with it own pressure sensors.

-

July 18, 2020 at 14:59 #14405

gFlyer

ParticipantYes, that’s right. But the sensor is looking similar, that’s why my question, can it be used by parallel wiring?

-

November 11, 2020 at 16:46 #14891

Karl WolffParticipant

Karl WolffParticipantI recently purchased N39070, AA1-C with an 0-320 STC. As part of my complete panel overhaul, I installed a CGR30P (rebate is only $400 now) to free up panel space and bring 21 century tech to the factory original panel. I can’t say enough about the situational awareness that instrument brings to the game. I have put over 50 hours on the bird since the modification in Aug (thank you Aero Services and Brandon at Santa Fe, Regional Airport) and have had almost no issues with the engine monitor, barring a loose probe that gave an intermittent EGT reading (Brandon tightened up the probe at no charge). The fuel flow indication, while mathematical rather than actual, is very accurate. Keep your fuel intake information up to date and it will give you good data.

I do not care for the yellow and red arc RPM information that EI factory programmed into the gage as it results in numerous alerts climbing out or any phase of flight with changing RPMs. The Lycoming manual says green arc to 2700 RPM, but the STC data proscribes the caution and warning arcs apparently to avoid FAA testing requirements according to FletchAir.

Overall, I would highly recommend any engine monitor upgrade, but I am very pleased with the information and display of the CGR30P.Karl Wolff

315.569.4509 -

November 12, 2020 at 12:25 #14895

Richard HarrisonParticipant

Richard HarrisonParticipantI have purchased the CGR-30P for my Yankee project. This will have a 0320-E2G with Ken Blackman’s STC. It also has Bill Scott’s HC STC on the engine so the redline as set on the 30P is 2650 RPM. No yellow arc.

My AA-1B that I installed a 0-320 in 37 years ago under the Collier / Fletchair STC has the redline set on the tach at 2510, with a yellow arc of 2280 – 2510. This airplane might not be a good candidate for an electronic tach that will be constantly nagging you for operating in the yellow arc.

Per the STC 2510 RPM is suppose to net you 144HP, and 2280 nets you 108HP. I remember Jimmy Collier saying the same thing that these limitations were excepted to reduce the effort needed to get the STC (back in 1977).

-

-

AuthorPosts

- You must be logged in to reply to this topic.